As part of her final year conservation project on the BA (Hons) Conservation course, Charlotte Okparaeke has chosen to use 3D printing in the treatment plan she has designed. This is the first time 3D printing has been used by a student in the Conservation Department and is a significant development.

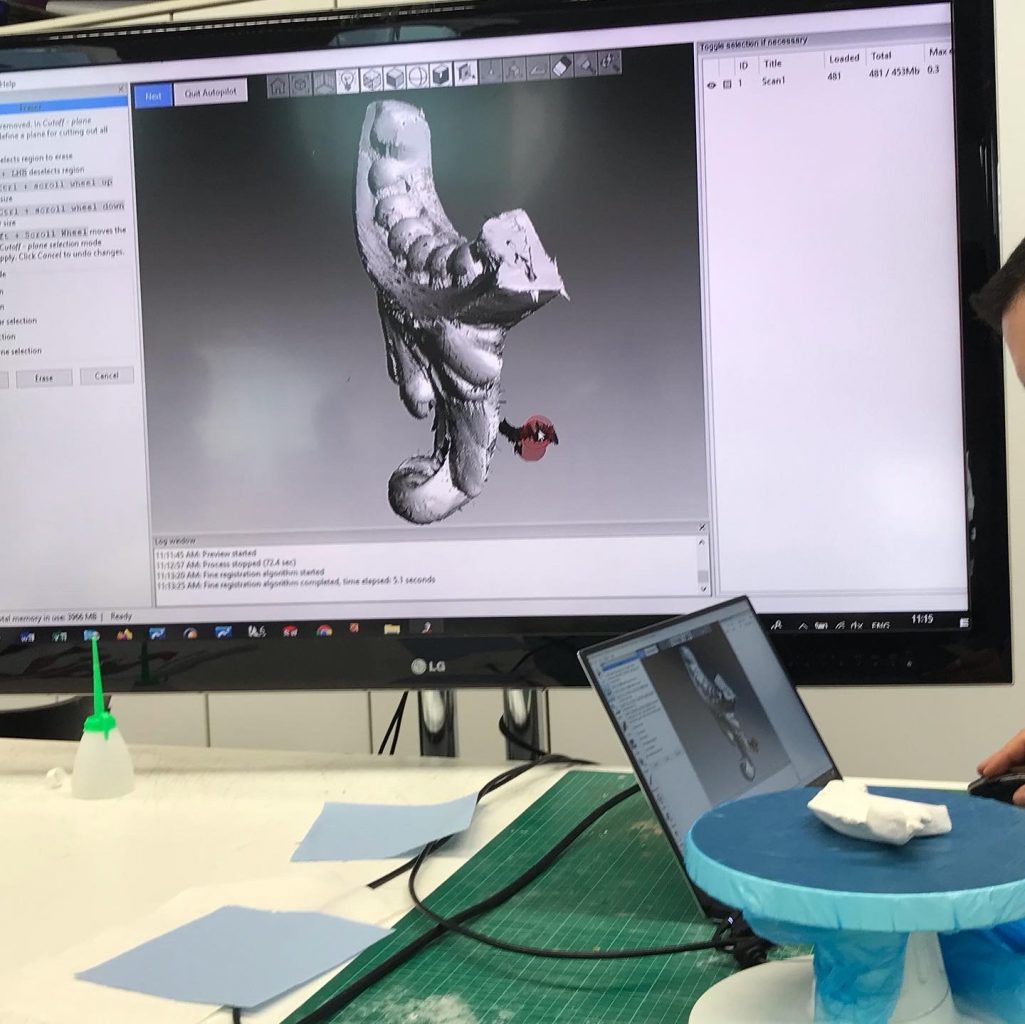

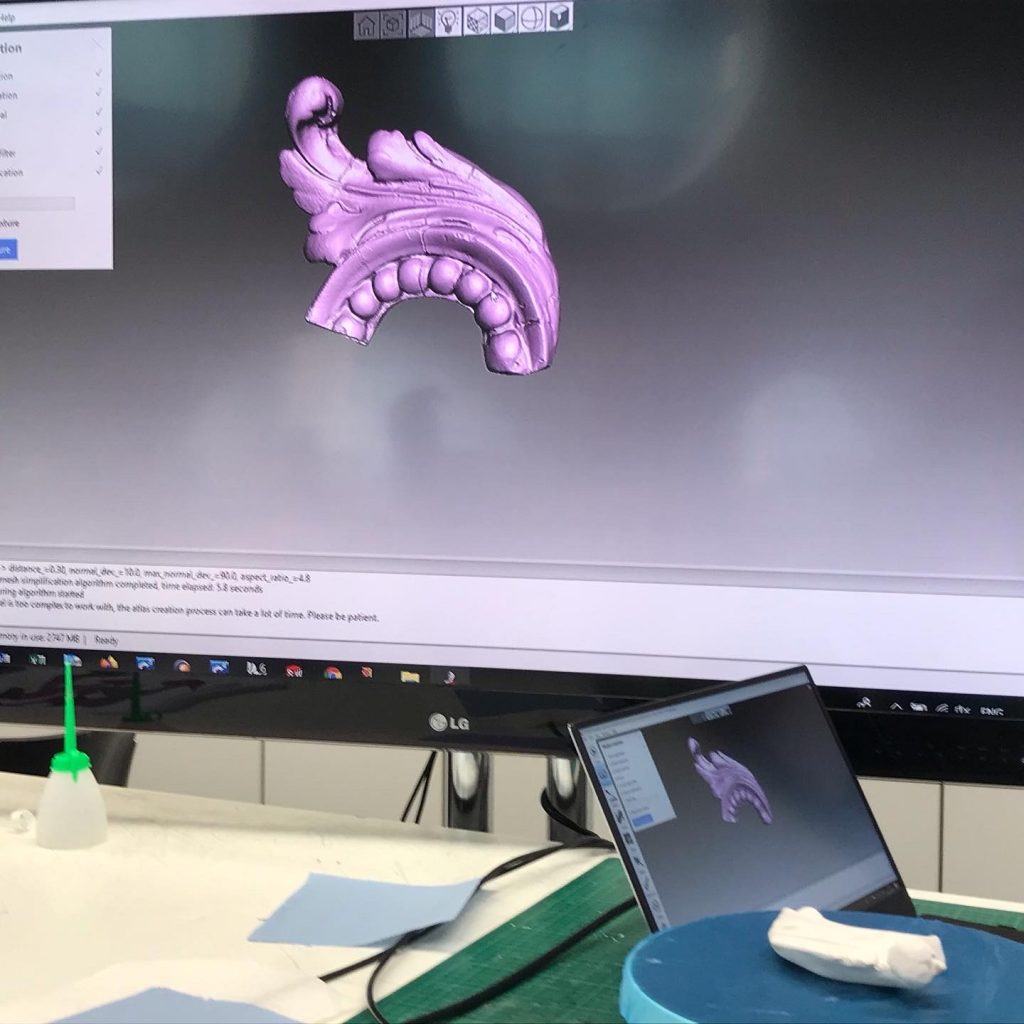

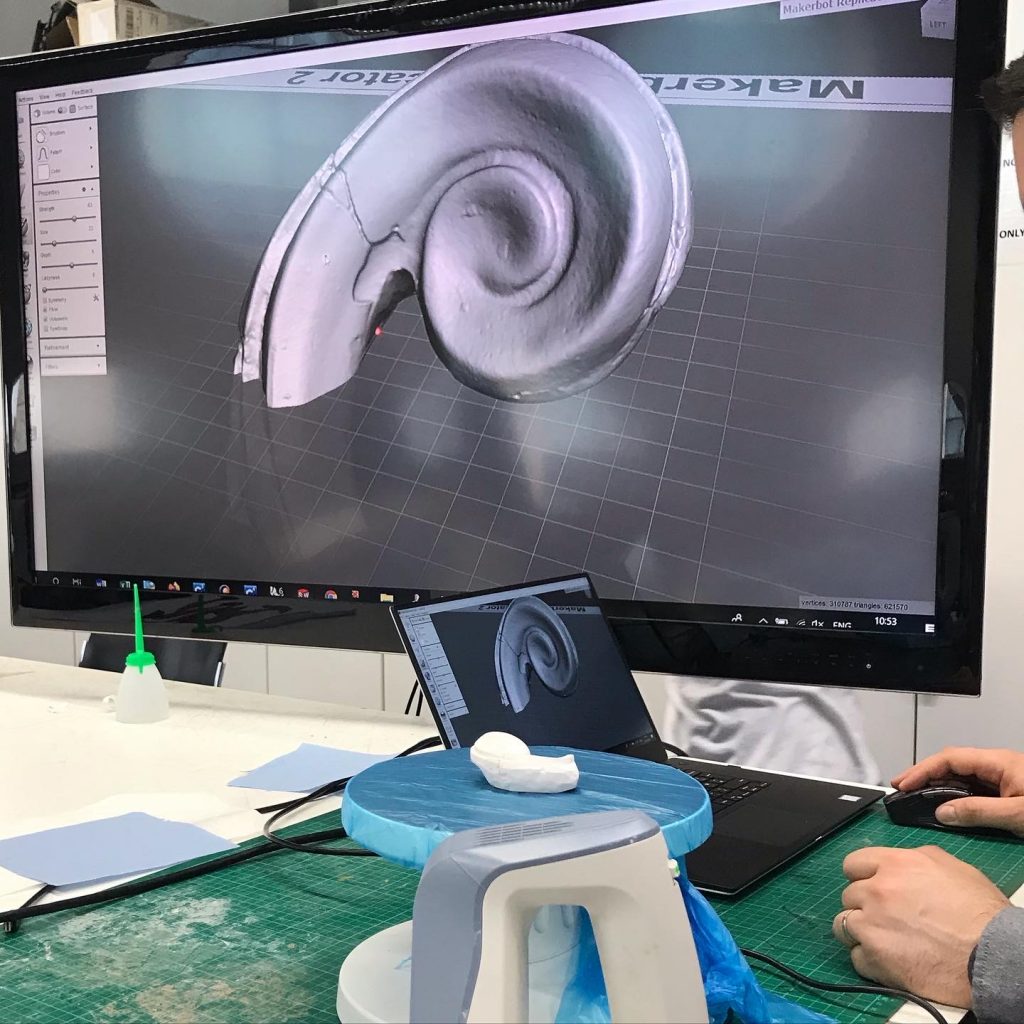

Charlotte is working on a Girandole gilt wood and compo mirror frame and is using the 3D scans to replace lost ornament on the frame where the reverse section is complete. A mould was taken from the surviving section and a plaster cast made. This cast was then scanned and will be refined and reversed with Meshmixer software, then 3D printed to obtain the mirror image.

The 3D print may be used as a positive from which a further mould and cast can be produced in the material of choice. Or it can be used as a negative, providing a ready-made mould. The scan can also be resized to allow for shrinkage in the final casting material, such as compo putty.

Charlotte intends to explore these different options to find the best solution for her object.

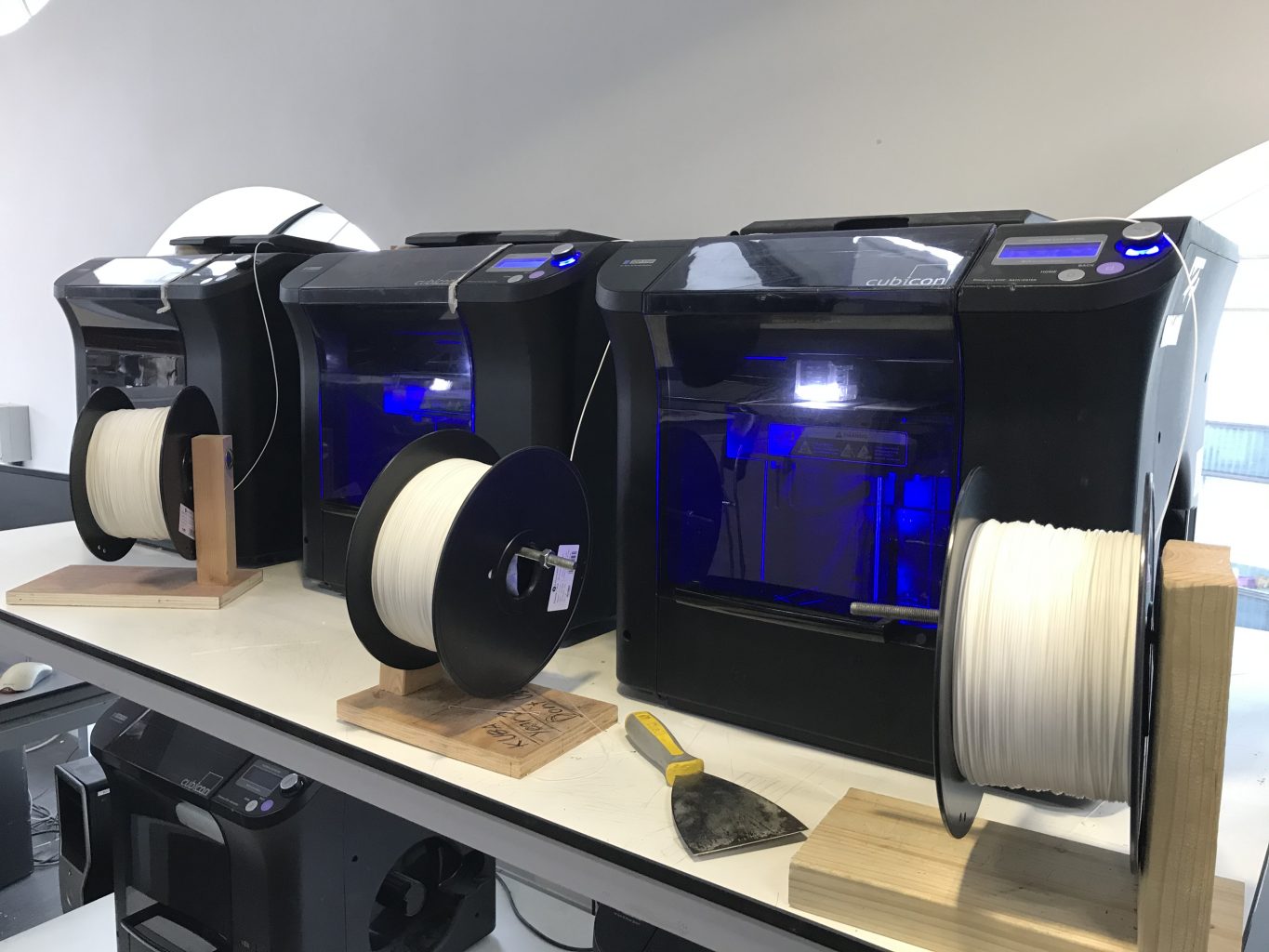

Support and facilities were provided by the prototyping department at our validating partner, Ravensbourne University London